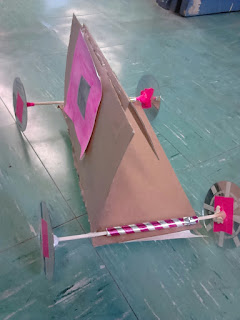

The first phase of this task was to put together the buggy by making wheels on axles and attaching them to the chassis or body. A wheel and axis unit is a simple machine-but it's not necessarily simple to make it work well as part of a buggy!

|

| image from http://www.education.com |

Lots of design choices were made here- the number, size and positioning of the wheels and axles, the type of axle and the shape, size and material of the chassis. In our design brief we asked the kids to make sure the wheels and axle could freely spin and that the whole buggy would be light but sturdy.

Now to get down to testing. Ready, set, go!! What happens when we launch our buggy down an incline? There's the sheer delight of making something that moves of course. It's equally fun to see what happens when you smash your truck into the wall at top speed.

The classic wonky wheel problem is common. These CD wheels are nice and big -which means they have a higher gear ratio than little wheels. Their lightness is generally good too-because the buggy is not weighed down by its wheels. But-there's a bit of an issue with their tendency to flop over.

In this car. a design solution was using foam blocks to keep the wheels straight. Unfortunately this was not sturdy enough to support the chassis without the wheels tilting. Sometimes troubleshooting can be maddening -especially when you are running out of time. A veritable tape marathon to keep the CD wheels straight and non-wavering.

In this car, lateral movement of the axles makes the buggy turn corners.

In the second phase of this challenge we asked the kids to add a jet propulsion engine to their buggy. A balloon taped up to a straw is attached to the back of the chassis and works rather like a rocket booster. In theory, the air escaping from the straw-provides thrust which pushes the buggy forwards.

Perhaps two balloons will work better than one?

This car was light -and low on friction- and sped some way with this nice short balloon nozzle.

The finishing touch: add your own logo to the racing car to give it a personal touch. This was an great workshop of testing and improvement. Well done kids.

These design workshops are made possible by the Toronto Arts Council.

No comments:

Post a Comment